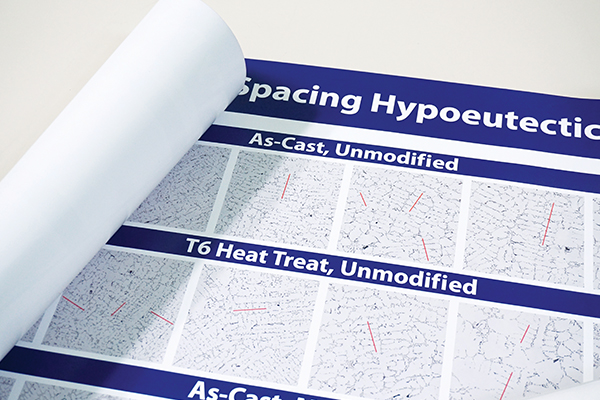

SDAS Hypoeutectic Aluminum-Silicon Alloys Wall Chart

-

$55.00

-

$41.25

-

$27.50

-

List Price $55.00

Member Price $41.25

Corporate Member Price $27.50

Product No: CH1800; Size: 39 in. x 27 in.

An important microstructural feature of hypoeutectic aluminum-silicon alloys is the secondary dendrite arm spacing (SDAS). Since the SDAS decreases with increased cooling rates, it is often used to estimate the cooling rate in castings. In addition, the SDAS can be used to estimate tensile properties.

This new wall chart was developed from the AFS Aluminum Division Technical Committee project where an A356 aluminum-silicon alloy was melted, treated, and poured into an Aluminum Association-certified stepped mold. Two melt compositions were tested, one with grain refiner additions and one without. The solidified casting was sectioned in each step and samples from these sections were prepared metallographically to measure the SDAS. Each step represents a different cooling rate and therefore produces a different SDAS.

The chart provides a reference to estimate SDAS from your cast microstructures showing 32 images from 10 µm to 100 µm in the As-Cast and T6 Heat Treated, unmodified or modified conditions. The chart also shows the relationships between the cooling rate, mechanical properties and the SDAS.